What is Machine Vision?

Definition and Overview

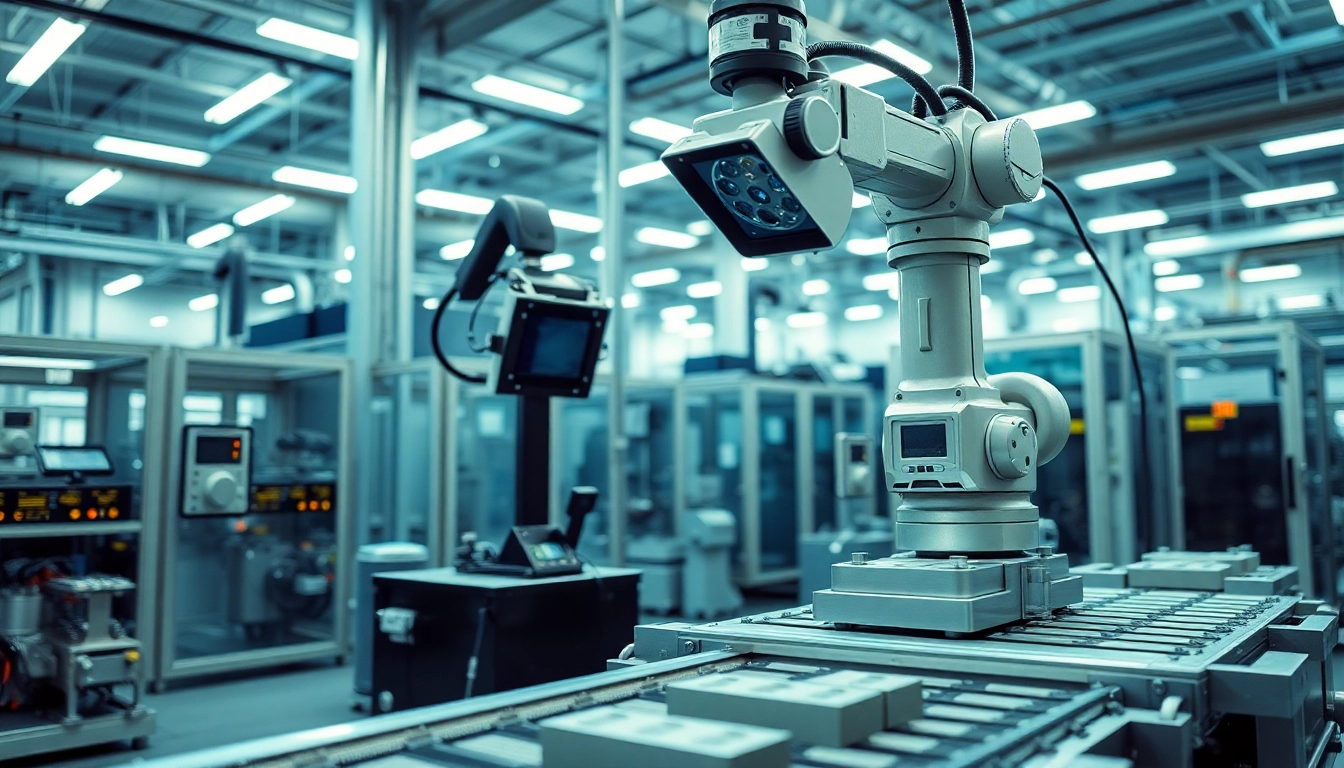

Machine vision is a branch of technology that enables machines to interpret visual information from their environment. It encompasses the use of computers and cameras to capture and process images for various applications, particularly in industrial settings. The key function of machine vision systems is to automate visual inspection and analysis, improving efficiency, accuracy, and consistency in production processes.

Key Components of Machine Vision Systems

A machine vision system typically consists of several key components:

- Cameras: Digital imaging cameras capture visual data. The choice of camera—2D or 3D—depends on the application.

- Lighting: Proper illumination is crucial for enhancing image quality. Different lighting techniques are applied based on the object’s surfaces and the environment.

- Processing Unit: This includes hardware like CPUs or GPUs that run software algorithms to analyze the captured images.

- Software: Algorithms process the images, extracting features to make decisions based on predefined criteria.

How Machine Vision Works

Machine vision works through a series of steps that transform raw visual data into usable information. The process typically follows this sequence:

- Image Capture: The machine vision system uses cameras to take pictures of objects or scenes.

- Image Processing: Captured images are processed using software algorithms that can analyze patterns and detect defects.

- Decision Making: Based on the analysis, decisions are made—such as identifying defective products or guiding automation systems.

- Feedback Loop: The system may also include feedback for continuous improvement, ensuring consistency and accuracy in future operations.

Applications of Machine Vision

Quality Control and Defect Detection

One of the primary applications of machine vision is quality control. It enables manufacturers to detect defects at various stages of production, ensuring that only products that meet specified standards are shipped. By implementing machine vision, companies can:

- Identify surface defects, such as scratches or dents.

- Monitor dimensions and tolerances to ensure products meet design specifications.

- Perform materials inspection and verification throughout the production process.

Automated Inspection in Manufacturing

Automated inspection is essential in manufacturing settings where speed and accuracy are paramount. Machine vision systems facilitate:

- Assembly Verification: Ensuring each component is correctly positioned.

- Label Inspection: Verifying correct labels and barcodes for compliance.

- Packaging Inspection: Checking for proper seals and package integrity.

Machine Vision in Robotics

In robotics, machine vision plays a critical role in enabling robots to interact with their surroundings. Robots equipped with machine vision systems can:

- Recognize and manipulate objects, enhancing automation in warehouses.

- Assist in autonomous navigation, crucial in scenarios like self-driving vehicles.

- Conduct complex tasks such as precision surgery in medical applications.

Benefits of Implementing Machine Vision

Improving Efficiency and Accuracy

Machine vision enhances both efficiency and accuracy in operations. By automating visual inspection, organizations can reduce human error and speed up processes, leading to:

- Increased throughput with minimal downtime.

- Enhanced precision in measurements and quality assessments.

Cost Reduction Strategies

The introduction of machine vision systems can lead to significant cost savings for businesses. Some notable strategies include:

- Minimizing waste by identifying defects early in production.

- Reducing labor costs associated with manual inspection tasks.

- Decreasing rework and returns, ultimately lowering operational expenses.

Enhancing Product Quality

By integrating machine vision into production processes, companies can achieve higher product quality. This is accomplished through:

- Consistent monitoring and real-time quality assessments.

- Data-driven insights that enable continuous process improvement.

- Standardization of inspection protocols across various production lines.

Types of Machine Vision Systems

2D vs. 3D Machine Vision

Machine vision systems can be classified into 2D and 3D systems based on their imaging technology:

- 2D Machine Vision: This type captures flat images and is predominantly used for identifying surfaces and defects.

- 3D Machine Vision: Utilizes depth perception to provide dimensional data, offering insights about the shape and volume of objects, critical for applications in robotics and assembly.

Smart Camera Systems

Smart cameras incorporate image processing within the camera itself, allowing for faster decision-making on-site and reducing the need for external processing units. They are preferred for their compactness and reliability in applications such as:

- Edge inspection in automation.

- Mobile applications where space constraints are a factor.

Technology Integration in Machine Vision

Advancements in machine vision technology are increasingly centered around integration with other systems, such as:

- AI and machine learning for improved data analysis.

- IoT for real-time monitoring and analytics.

- Cloud computing for data storage and processing scalability.

Future Trends and Technologies in Machine Vision

AI and Machine Learning Integration

The integration of AI and machine learning is set to revolutionize machine vision by enabling systems to learn from data and improve over time. This move toward intelligent systems will lead to:

- Improved predictive maintenance capabilities.

- Enhanced defect recognition methodologies through advanced algorithms.

- Customization for specific applications, tailoring machine learning outcomes to industry needs.

Advancements in Imaging Technologies

Future advancements in imaging will shape the performance of machine vision systems, including:

- Higher resolution cameras that provide more detail for inspection.

- Advanced lighting technologies that improve image quality under varying conditions.

The Role of Machine Vision in Industry 4.0

As industries move towards automation and smart manufacturing, machine vision will play a pivotal role in Industry 4.0 initiatives. Its key contributions will include:

- Facilitating seamless communication between machines.

- Enhancing data analysis for smarter decision-making.

- Contributing to overall operational efficiency and productivity by integrating with other technologies like robotics and IoT devices.